Ever thought about turning your CNC machining skills into a full-fledged business? Maybe you’ve been working in a shop for years, fine-tuning your craft, and now you’re ready to be your own boss.

Or maybe you’re fascinated by manufacturing, love working with your hands, and see CNC machining as a solid, profitable way to build something real—something that lasts.

Sounds exciting, right? Well, it is. But let’s not sugarcoat things. Starting a CNC machining business isn’t as simple as buying a machine, finding a few clients, and raking in cash.

It takes planning, investment, patience, and a whole lot of problem-solving. Mistakes will happen, costs can pile up, and finding customers won’t always be easy.

But here’s the good news: CNC machining is in demand. Industries like aerospace, automotive, medical, and robotics are always looking for high-quality precision parts. And if you’re good at what you do—if you deliver consistent, top-notch work—word spreads fast.

So, how do you go from an idea to a fully operational business? How do you make sure you’re not just another person with a machine but someone who makes a living from it?

1. What’s the Plan? Define Your Business Goals

Before even thinking about machines, software, or shop space, you need to figure out what kind of business you want to run.

Are you planning to start small—maybe just a one-person operation out of your garage? Or do you see yourself growing into a full-fledged shop with multiple employees and machines? Both paths are valid, but they require different approaches, budgets, and mindsets.

Think about what kind of work excites you. Some machinists specialize in custom one-off parts for prototypes, while others focus on high-volume production for industries like automotive or aerospace. Do you want to take on large contracts with strict deadlines, or do you prefer working on small, high-margin custom jobs?

2. Choosing Your Niche – What Kind of CNC Work Will You Do?

CNC machining isn’t a one-size-fits-all industry. There are plenty of ways to specialize, and finding the right niche can set you apart from the competition.

Maybe you want to focus on precision machining for medical devices. Or perhaps you’re more interested in automotive parts, firearm components, or custom metal art. Each industry has different demands, pricing models, and customer expectations.

The best way to choose a niche? Research. Talk to local manufacturers and businesses to see what kind of CNC work is in demand. Look at competitors in your area—what are they offering? More importantly, what gaps can you fill?

The goal is to find a balance between what you enjoy, what you’re good at, and where the money is.

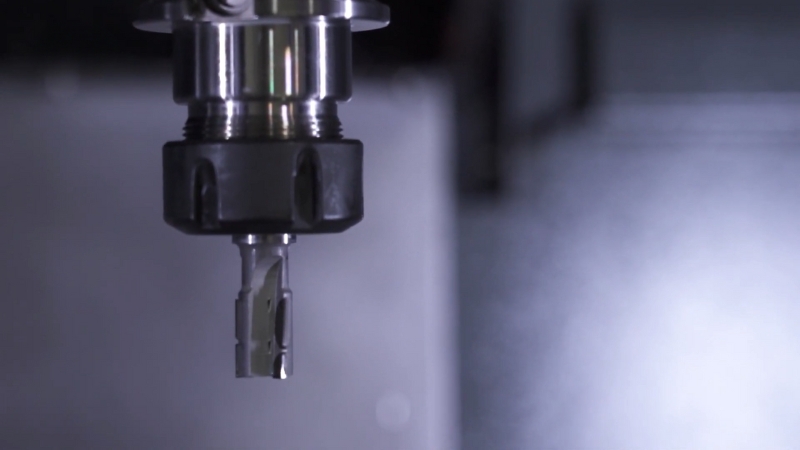

3. Buying the Right CNC Machines and Equipment

View this post on Instagram

Here’s where things start to get serious. Your machine shop lives and dies by the quality of your equipment. Buy the wrong machine, and you could be stuck with an expensive piece of metal collecting dust.

What Kind of CNC Machine Do You Need?

There are a few different types, each with their own strengths:

Your choice will depend on the type of work you plan to take on. If you’re not sure, a CNC mill is a safe and flexible starting point.

New vs. Used Machines – What’s the Best Choice?

If you’re on a budget, a used CNC machine can save you tens of thousands of dollars. Just be careful—repairs and maintenance can add up if you don’t buy from a reputable source.

A new machine, on the other hand, comes with a warranty, customer support, and the peace of mind that it won’t break down right away. If you can afford it, new might be the way to go.

4. Setting Up Your Shop – More Than Just Machines

You’ve got your machine, but where are you going to put it? Setting up your shop is more than just finding a place to park your equipment.

Space and Layout Matter

A cramped, disorganized shop will slow you down. Think about the flow of materials—where raw stock comes in, how it moves through the machining process, and where finished parts go. A clean, efficient setup makes a huge difference.

Power and Ventilation

Many CNC machines require 220V or even three-phase power, so check if your shop can handle it. Good ventilation is also key—machining produces heat, and proper airflow prevents overheating.

Safety First

Don’t skip this part. Fire extinguishers, emergency stops, eye protection, and good lighting are non-negotiable. Accidents happen, but a well-prepared shop minimizes risk.

5. Learning CNC Programming and Software

Learn more about the powerful MANUFACTURING VALUE OFFERS designed to enhance your CNC programming capabilities and seamlessly connect each stakeholder within your product development ecosystem. Check out this on-demand session of SOLIDWORKS LIVE. https://t.co/2Binhtjc2x pic.twitter.com/J5BxMkygSf

— SOLIDWORKS (@SOLIDWORKS) August 26, 2024

Even the best machine is useless if you don’t know how to use it.

Essential CNC Software to Learn

And don’t forget G-code—the language that CNC machines run on. If you can read and tweak G-code manually, you’ll have way more control over your machine.

6. Pricing Your Work – Charge What You’re Worth

One of the biggest mistakes new CNC business owners make? Undervaluing their work.

Pricing isn’t just about material costs. It includes:

Look at what competitors charge, but don’t just race to the bottom. Quality work commands a higher price, and customers who value quality will pay for it.

7. Finding Customers – How to Get Your First Jobs

A CNC business without customers is just a really expensive hobby. Getting those first jobs is crucial.

Start by telling everyone you know. Word of mouth is powerful in this industry. Set up a simple website showcasing your work, and use social media to post videos and pictures of what you’re making.

Reach out to local manufacturers, engineering firms, and metal fabrication shops. A well-crafted email introducing your services can open doors.

Platforms like Xometry, ThomasNet, and Maker’s Row are also great places to find work.

8. Scaling Up – Growing from One Machine to a Full Shop

Once jobs start coming in regularly, it’s time to think about growth. More machines? More employees? Expanding into new industries?

Some smart ways to scale include:

- Investing in automation – Robotic loaders and pallet changers boost efficiency.

- Adding complementary services – 3D printing, laser cutting, or welding can open new revenue streams.

- Building a reliable team – Hiring skilled machinists lets you take on bigger projects without burning out.

Growth should be steady, not rushed. Expanding too fast can be just as dangerous as not growing at all.

Final Thoughts – Is a CNC Machining Business Right for You?

Starting a CNC machining business isn’t easy. It takes money, patience, and a constant drive to improve. But if you love making things, solving problems, and working with precision, there’s nothing quite like it.

As CNC technology continues to evolve, staying ahead of the curve and embracing new advancements will be key to maintaining a competitive edge.

Start small, learn everything you can, price your work properly, and always deliver quality. Do that, and success will follow.

Now, are you ready to make some chips?